SHRINKING TUBE/HOSE LDPE

PE is the abbreviation for polyethylene. Plastic films made of polyethylene are therefore also referred to as PE films. Heat shrink tubing is used to prevent the load from slipping. This means that the shrink-wrapped pallet can withstand certain lateral forces during transport.

SHRINKING TUBE/HOSE

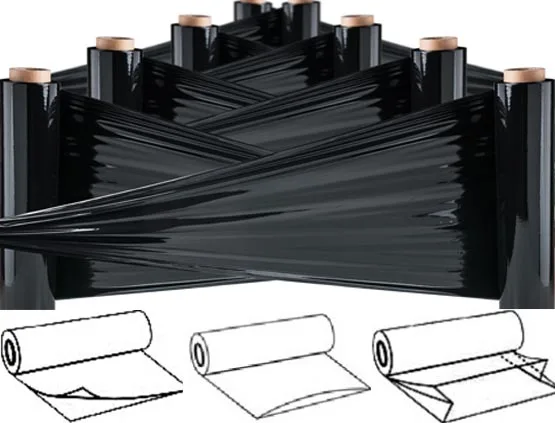

It is characterized by a wide range of possible applications and allows you to create tailor-made packaging. High tear and puncture resistance. Shrinking Tube is produced in rolls. Special dimensions are also possible.

When exposed to heat, the film contracts significantly and thus offers optimal protection for your product.

It also provides reliable protection against dirt and moisture. We produce Shrinking Tube in all variants and designs. TOP quality directly from the manufacturer.

The film material contracts when the shrink gun generates heat and the film wraps around the product to be protected. A distance of approx. 30 cm from the shrink gun to the shrink film should be maintained. The packaged items under the shrink hood are not damaged in any way by the heat. Shrinkage should always begin at the bottom of the pallet and then continue upwards to ensure optimal shrinkage.

Product data Shrinking Tube

| Materials | LDPE film, compound film (monoaxially shrinking) |

| Surface | lubricated or non-slip |

| Width | from 25 mm to 3600 mm |

| Length | according to customer requirements |

| Strength | 50 my to 250 my |

| Colour | transparent, coloured transparent, opaque |

| Printing | flexographic printing, signature printing, embossed printing |

| Packaging | on a roll |

| Types | folded, with side gussets, as tubular film |

| Additional qualities | anti-static, anti-blocking, anti-fog, electrical discharge capacity, meets food regulations, low flammability, UV-resistant |

We process polyolefins such as high pressure (LDPE), medium pressure (MDPE), mixed films made of the aforementioned materials as well as polypropylene (PP) and various composite films. All raw materials and masterbatches we use are certified. A REACH declaration of conformity is available for each type of raw material. Every batch delivered has a batch certificate. These are managed and monitored in our quality management system. Depending on requirements and application, also via FDA approval.

An in-house quality assurance system ensures that all products can be tested and certified if required.

BUY OUR SHRINKING TUBE/HOSE-PRODUCTS DIRECTLY FROM THE MANUFACTURER!

Our bag products are environmentally friendly because they are 100% recyclable, rot-proof and neutral to groundwater. Polyethylene can be re-melted, i.e. it is completely recyclable and can therefore be reused in a different form. Our production waste is recycled in our own regenerated plant for reuse.